Norway’s first autogenous welded storage tank is produced at Oslo Svesiebedrift

Norway’s first autogenous welded storage tank is produced at Oslo Svesiebedrift

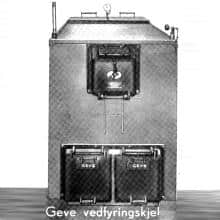

Welded cooking pots and wood boilers complements the range of products

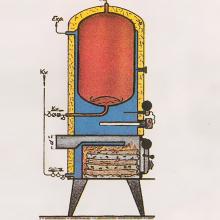

Development of wood-burning boilers which provides both heat and hot-water

Production of potato collector cogs and planting equipment during the war

Production of copper-lined storage tanks 200 – 50,000 litres resumes

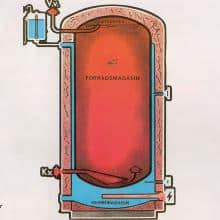

Provision storage tanks tripled the capacity while only taken half the space

“TRIPLEX” and “COMPACT” heating units for oil and wood/electrical units

“NORTHEM” integrated heating unit and storage tanks is launched

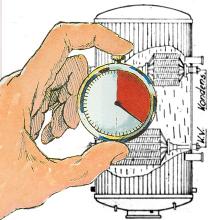

The «SAFE» – triple-valve and surface mounted thermostat is introduced

Heaters heated directly by electricity simplifies installation and operation

First in the world to produce stainless steel storage tanks which increases lifespan.

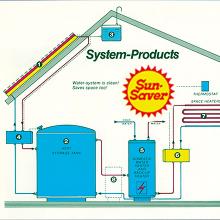

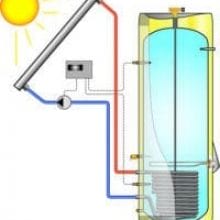

The “SUNSAVER” solar-heated storage tanks are launched

Top-mounted mixing valves becomes standard, resulting in huge resource savings

The tank-in-tank unit “PROGRESS” water heater line is introduced for heat pumps

The “TURBO” system with plate exchanger revolutionises heat-up times

The “MAXI” large storage tanks 500-1000 liters becomes industry standard

The warranty is doubled on the stainless steel pressure tank

The new “ECO FOAM” insulation saves more than 500 million kWh in 10 years

“ENERGY SAVER” for grey water reuse results in huge Energy Efficiency savings

OPTIMA serien tredobler kapasiteten og øker virkningsgraden for alle varmepumper

“EXPANSION” is introduced with a fully integrated expansion solution

Upplåter tillverkning av specialkomponenter och etablerar OSO Manufacturing AB i Sverige

As a consequence of the implementation of the ErP directive in Norway,

integration of vacuum panels improves insulation

The “DELTA” series receives rating “A” from ErP – best in class

OSO Manufactoring AB startar produktion av stora tankar i rostfritt stål, och volymer upp till 15 000 liter!

OSO Hotwater AB ble etablert i 2019.

OSO releases “VERSA“, “WALLY“, and the “OPTIMA” series

Pioneering work in product development and continuing efforts to do the best for people and environment have resulted in a number of environmental awards and recognitions. Of particular importance has been the National Honorary Award “Glassbjørnen” (the Glass Bear) for unique environment efforts through 30 years, the “SCANVAC” award for the Best Environmental Company in Scandinavia and the “Best environment and Energy Efficiency product” for introducing foam insulated storage tanks. The accolades inspires us to further develop our vision of environmental protection.

The Welding Award – National Technology Companies’ Union

The Business Prize – Buskerud County Council

Work Environment Award – The Center for Work Environment

The Welding Award – Norwegian Welding Technical Union

Product Award – Olympia exhibition in London

Internal Control certificate no 1 – National Institute of Technology

Best Export Company – Buskerud Industry Union

SCANVAC Award – Best Environmental Company in Scandinavia

SOFUS Award – The Bisycling Association

SOFUS-priset – Sykkelrådet

Norway’s first EMAS environmental certificate

Best environment report – GRIP w/ The Agency for Environmental Protection

Energy and Environmental Technology Award – Perfect Buildings Association

Environmental Honorary Award “Glassbjørnen” – GRIP w/ The Agency for Environmental Protection

Logistical Award – The Norwegian Business School

Best Environmental Company in the Industry – Varme & Bad HVAC company

Best Environmental Company in the Industry – Varme & Bad HVAC company

H&V News Award UK – Best new product on the market

Best environmental company in the industry – Heating & Bath

H&V News Award UK – Best New Product on the Market

Certificates and approvals held by OSO Hotwater AS.

OSO products are certified to relevant standards according to model and type.

OSO products are certified to relevant standards according to model and type.

Marine and industrial products:

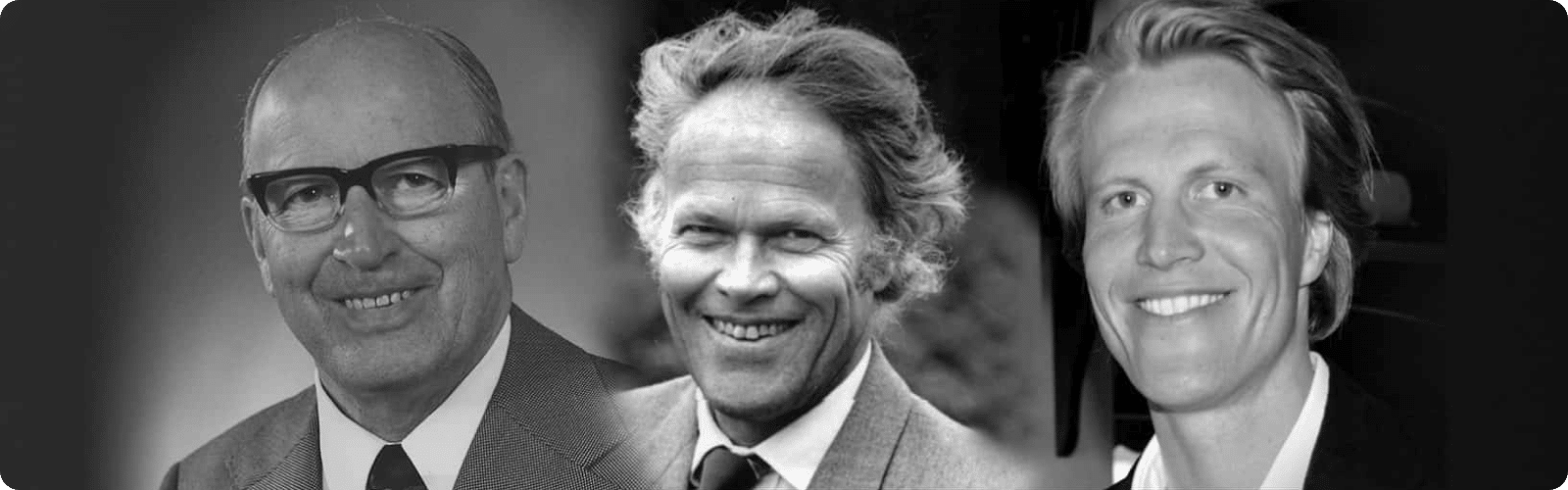

The founder – Reidar Frölich Braathen – started “Oslo Sveisebedrift, Oslo” (OSO) in Oslo in 1932, as one of the first welding shops in Norway. Frölich Braathen was both a blacksmith and a lieutenant in the Norwegian air force and among the first in the country who mastered both electric and autogenous welding. With minimal resources he created the first Norwegian welded water heater. Thanks to his continuous innovation and dedication Frölich Braathen employed 100 people by 1940. His 50 years of experience became the foundation of OSO Hotwater AS – a Norwegian industrial adventure.

2nd generation – Chris Reidar Braathen – was very much involved in restoring the factory after the war. In 1964 Chris Reidar established OSO factory by the Drammen river, where the production of water heaters is still located today. Chris Reidar was a technician and had great commitment and drive, in addition to idealistic ideas. He has, during his more than 50 years in OSO, combined industry and environmental protection in a unique way and has given OSO the recognition as one of the leading environmental enterprises in the Nordic countries, something which has led to several environmental awards and accolades.

3rd generation – Sigurd Braathen – continues to lead OSO with a clear objective to still be a family business located in Norway. Dedicated to improving OSO products and processes, Sigurd continues to build the company brick by brick, and is proud of the fact that OSO has become one of the most robotized companies in Norway. The pioneering spirit lives on with product innovations featuring integrated solutions, ground-breaking material technology and added value for our customers.

THE COMPANY HAS THREE MAIN MARKETS:

A NORWEGIAN INDUSTRIAL ADVENTURE THROUGH 3 GENERATIONS:

OSO was one of the first environmental enterprises in Norway with more than 50 years of efforts and investments to unite people, environment and industry. The emphasis on the environment started with Reidar Braathen Jr. in 1956. He created “The most environmental company in Scandinavia” (SCANVAC award). After 50 years of continuing effort for both indoor and outdoor environments, GRIP together with the Minister of Environmental Protection, Arild Hareide, awarded the special “Glassbjørn”-award to OSO for our effort to save the environment.

Thanks to the loyalty of our customers, OSO has become renowned for best practice for both its manufacturing of water heaters as well as environmental protection. Products with extremely long lifecycle, and the lowest heat loss of any storage tanks on the market are some of our biggest contributions to the environment, in addition to zero-emission production and no toxic waste released of any kind. Love and care for nature is the basis for our engagement in protecting the environment, our objective is the same today as 50 years ago: PROTECT OUR BEAUTIFUL PLANET.

Among the most important environmental efforts are:

The OSO Environmental Fund has contributed to these projects:

OSO Hotwater AS is since 2015 the most robotized manufacturing company in Norway. This has been necessary to keep our business in Norway instead of moving production to low-cost countries as is done by many manufacturing companies these days. By leaving the heavy lifts and repetitive tasks to robots we have liberated the human resources for more constructive tasks, while in the process creating a working environment where health and wellbeing is in focus. OSO has won several awards for our working environment, and is certified in this area in accordance with ISO 45001.

Over 85 years OSO Hotwater has earned the trust from suppliers, co-workers and customers. We are still going to earn, and manage, this trust in an exceptionally good way, and value the opinion of our partners.

Our guiding targets:

Information about the product owners’ rights

OSO Hotwater’s web pages may contain or provide references to trademarks, patents, owner information, technologies, products, processes or other rights of OSO Hotwater Group AS. No license or rights to any of these trademarks, patents, information about owners, technologies, products, processes or other rights of OSO Hotwater Group AS are assigned or granted to users of this site.

A number of the products on the OSO Hotwater website may be or are protected by patents or trademarks. This includes both production technology and / or complete products. These may be specified in the site’s texts, but are not required to be protected by the patent. The underlying technology for the production of the product may or may not be the property of OSO Hotwater.

It is to be noted that all violations of OSO Hotwater Group AS’ rights will be subject to legal prosecution.

Information about the legal terms relating to our web site

This site, including its content, is fully owned by OSO Hotwater. We reserve all rights to this material.

You may store extracts from the OSO Hotwater website on your personal computer and print copies of these for personal, non-commercial use. You are permitted to use and distribute necessary and minor extracts from the OSO Hotwater website to facilitate direct links / pointers to the pages, or linking for search services on the Internet.

Any other use, such as reproduction, translation, processing, arrangement, and any other modification, distribution or storage of this Site in any form and by any means wholly or in part, is not permitted. The information presented on this site will not be accurate, up to date, or current for circumstances surrounding a particular issue. We can not assume any liability for inaccuracies or omissions. Any decisions made based on information contained on this site are at your sole discretion.

Neither OSO Hotwater nor any of OSO Hotwater subsidiaries accept liability for any direct, indirect, special, substantial or other loss or destruction of any nature which may result from access to or use of this site or its content. This notice is subject to and must be interpreted in accordance with Norwegian law.